working principle of brinell hardness testing machine|brinell hardness testing machine diagram : Chinese The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .

web11/7/2022. As quatro salas com pouco mais de 600 lugares tiveram um investimento em torno de R$7 milhões. O primeiro cinema em Canela, no Rio Grande do Sul, será .

{plog:ftitle_list}

Aval 11 horas. Aval 12h45min. Aval 14 horas. Aval 15h45min. Aval 17 horas. Aval 18h35min. Confira agora o resultado do sorteio do jogo do bicho Aval válido para Recife .

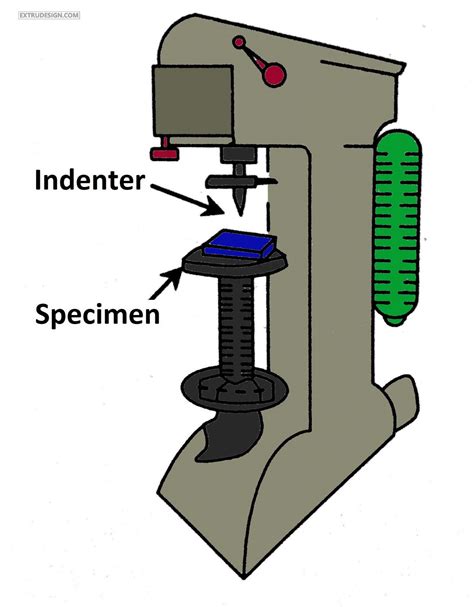

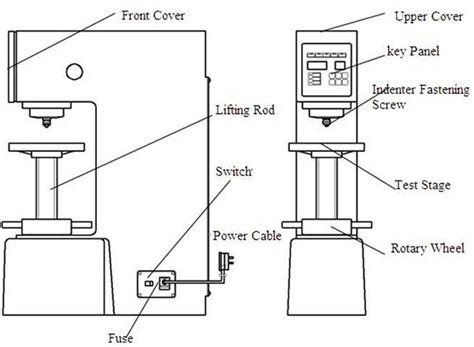

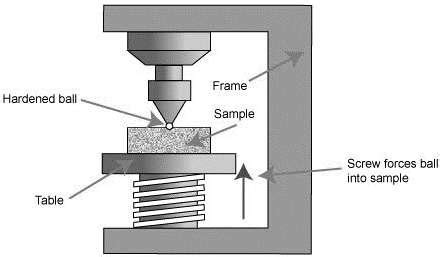

The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Harder materials will generate shallow . See moreThe Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for . See more

brinell hardness testing procedure

Once the average indentation diameter is measured the Brinell Hardness Number (BHN or HBW) can be calculated using the following Brinell hardness test formula: Here, 1. F=Applied force, in kgf 2. D=diameter of indenter, in mm 3. d=diameter of . See moreThe BHN or HB values are mostly reported using only the number. So, it seems there is no unit for the Brinell Hardness Number. . See moreThe general principle of the Brinell indentation hardness test consists of two steps: The indenter is brought into contact with the test specimen in a direction perpendicular to the .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .

Indentation hardness became the new standard, leading to a series of advanced test methods including the Brinell, Vickers, and eventually Rockwell hardness tests. Micro hardness testing still employs indentation to probe the surface of a sample and measure the resulting impression. The principles vary from test-to-test, but – typically – a .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell .When is the Brinell hardness test used? Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with .This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the indenter of the equipment is forced to make a residual depth on the test specimen.

2. Brinell Hardness Testing Brinell hardness testing employs a “Brinell hardness testing machine” and a spherical indenter to measure hardness. A known load is applied, and the resulting impression’s diameter is measured. This method is suitable for materials with coarse surfaces or irregular shapes and is widely used in the testing of .Conventional hardness testers, like Rockwell, Brinell or Vickers machines, require the test piece be brought to the testing device; but this is not always possible. Portable testing devices have been developed that permit in-situ hardness measurements thus offering quick and economical supplements to conventional, stationary testing machines.

Principle of Rockwell hardness testing . The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type .As shown in Fig. 3.12, the Vickers hardness curve remains practically straight at all hardness values, whereas at hardness above 300 kg/mm 2 the Brinell hardness curve starts bending to result in a lower value and it diverges remarkably causing an unacceptable hardness value above 600 Brinell, where the Vickers test is considered to be a .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

A Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. Rockwell hardness machine. A machine capable of performing a Rockwell hardness test and/or a Rockwell superficial hardness test and .The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. In brinell testing machine the load is applied by a .

The residual indentation size of the indenter can be measured using optical measurement methods. Among the standardized optical hardness testing methods are the Brinell hardness test (ISO 6506, ASTM E10), the .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information . With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness! . According to this definition, all hardness testing methods are ultimately based on the same principle. An indenter (e.g. ball, cone, pyramid, etc.) is pressed with a certain force into the material .How Does Hardness Testing Work? The mechanism of hardness testing involves applying a standardized, rigid tool known as an indenter onto the material under examination. This indenter is pressed into the sample for a predetermined duration (typically measured in seconds) and with a specified load (force) applied behind it.

Metallic materials — Brinell hardness test — Part 1: Test method 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines. For some specific materials and/or products, particular International Standards exist (e.g .

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. . Following surface preparation, a light load is applied to the indenter (usually either 3 or 5 kgf) to zero out the testing machine. Then, a heavy load (anywhere from 15 kgf to 150 kgf, depending on the .The Brinell scale characterizes the indentation hardness of materials through the scale penetration of an indenter, loaded on a material test-piece. Tinius Olsen has many types of hardness testers available that can rapidly and accurately determine the hardness value of a wide variety of materials including metals, plastics, large parts and .

METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l). 2 Normative referencesLearn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts.

brinell hardness testing machine diagram

Telebrineller Brinell Hardness Testing System Principle Of Operation. Select a test bar with a known Brinell Hardness Number (BHN), closely mirroring the expected hardness of the specimen under examination. Consistent accuracy is maintained when the test bar BHN is within + or -15% of the specimen BHN and is of the same general material.Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. . 2.3 Functional and Calculation Principle for Brinell Sample Surface Force (F) HBW = Brinell Hardness HBW = Constant x HBW = 0.102 x d 1= (Mean Indentation-Ø) Test Load F 2F d +d 2 .

windows hard drive test tool

brinell hardness tester for sale

web22 de fev. de 2024 · About this app. With our app, you can create custom filters to monitor the live football matches you want to follow. Receive real-time notifications for your entry, .

working principle of brinell hardness testing machine|brinell hardness testing machine diagram